Material World: MycoWorks and Mycelium Thread

Material World is a weekly roundup of innovations and ideas within the materials sector, covering news from emerging biomaterials and alternative leathers to sustainable substitutes and future-proof fibers.

MycoWorks

Biomaterials technology company MycoWorks announced the opening date of what it’s calling the world’s first commercial-scale Fine Mycelium production plant. Set to commence operations on Sept. 20, the 136,000-square-foot South Carolina facility will have over 350 employees, allowing the company to produce millions of square feet of its mushroom-derived leather alternative Reishi product each year.

More from Sourcing Journal

“This is the moment the luxury industry has been waiting for; a plastic-free leather alternative that offers undeniable beauty and performance—at scale,” Patrick Thomas, former Hermès CEO and MycoWorks board member, said. “Now that the challenge of supply has been solved, brands will move quickly to commercialize items made with Reishi.”

The company’s proprietary Fine Mycelium technology production process “cultivates mycelium in a controlled environment,” the California-based company said, by engineering mycelium cells while they grow to create three-dimensional, densely entwined and inherently strong structures. As it’s grown under “precise conditions” in proprietary trays, each sheet of mycelium has an individual code that can be fine-tuned—from inoculation to harvest—to meet the specifications of its brand partners, such as Hermès, Ligne Roset and General Motors. And MycoWorks operates vertically via owning its technology stack instead of outsourcing or licensing.

“MycoWorks’ Fine Mycelium platform is an unprecedented advancement in materials,” Kiersten Stead, managing partner DCVC Bio and MycoWorks board member, said. “Opening the doors on the first commercial-scale factory has MycoWorks poised to answer the luxury industry’s desire to craft objects with natural alternatives to leather.”

The news comes as the company released test results comparing this year’s Reishi against last year’s, confirming that the new formula maintains its softness, tensile strength and tear strength while exceeding its targeted finish adhesion, bally flex and Martindale abrasion.

“There have been two barriers to the decade-long search for a luxury leather alternative: product quality and scalable manufacturing, MycoWorks CEO Matt Scullin said. “In 2016, we eliminated the first by introducing Reishi to the world, and in September 2023, we are answering the question of scale with this state-of-the-art facility in South Carolina.”

Dahsheng Chemical (DSC)

Foam manufacturer Dahsheng Chemical (DSC) has launched the Durapontex N-Series and is the first brand to use supercritical foaming technology (SFC)—a manufacturing process where gas is pumped into the foam while forming in the mold—at scale in the development of an insole.

“The DSC innovation team has achieved a significant milestone by successfully developing the Durapontex N-Series using supercritical foaming technology, which requires consistent high temperature and pressure control,” Johnson Chang, CEO of DSC, said. “The result is an athlete’s dream: unmatched rebound, resilience, and guaranteed high energy return.”

Designed for ultra-performance, DSC maintained precise control over the supercritical foaming environment while creating the new foam. “Supercritical foaming” refers to a method of creating a foam using a supercritical fluid, which is a substance at a temperature and pressure above its critical point, DSC said, further explaining that when a gas is in a supercritical state, it has both gas-like and liquid-like properties—ideal for athletic footwear. For the Durapontex N-Series, DSC infused the foaming process with nitrogen, resulting in a soft foam cell made with consistent room between the bubble-like cells that creates a lightweight insole. The company also uses supercritical foaming technology to create a very thin upper composite material that allegedly has “exceptional extendibility performance” capabilities.

“The ultra-light weight and extremely high resilience in the Durapontex N-Series is something we haven’t seen in the industry before,” Chang said. “We received great feedback when we athlete-tested the N-Series at the Portland Track Festival this year, that it was amazingly soft and bouncy, as well a new, favorite insole on the track.”

The series is available at various densities and rebounds, including the Durapontex N20 and the Durapontex N23. The N-Series foam is 100 percent recyclable to boot.

Mushrooms Inc.

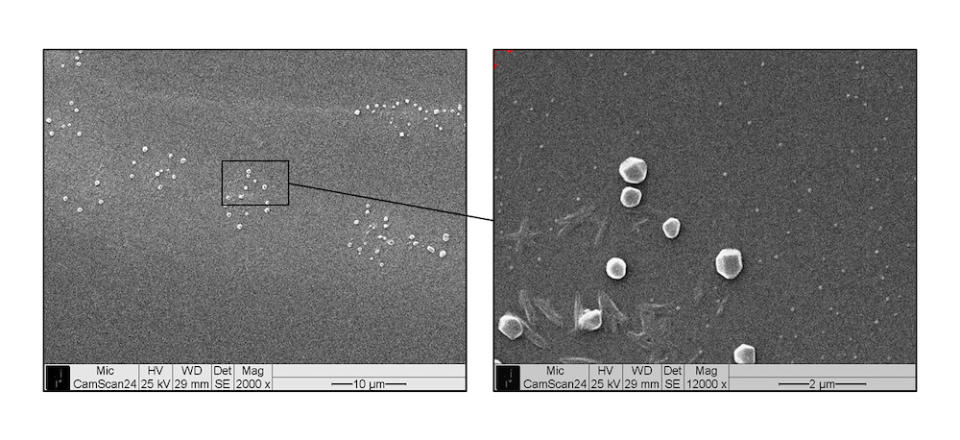

Sustainable textile innovator Mushrooms Inc. is in the final stages of filing a full patent application for its mycelium thread technology. The company, which is the first to trade on the U.S. stock market that’s focused on the industrial side of mushrooms, said it believes this is a step forward in its mission to “revolutionize” the textile industry.

Formerly known as Marijuana Strategic Ventures, Mushrooms Inc.’s first executed an exclusive license agreement for all rights to a provisional patent for a mycelium thread manufacturing method last August. The process “uses specific fungus to metabolize and biodegrade agricultural waste into a usable mycelia material,” lead scientist Robert Richardson said at the time. That mycelia are then esterified and spun into silky fibers that can be used for the apparel sector, among other applications. The resulting textile, which takes two weeks to grow, is inherently antimicrobial and possesses the ability for microbial detection.

“This project showcases that holding to high environmental standards does not mean a sacrifice of technological advancements; in fact, it exemplifies the opposite,” Kimberly Carlson, CEO of Mushrooms Inc., said. “By working in partnership with nature, it gives back tenfold.”

Dr. Hyder Ali Khoja is the senior lead scientist for the Myco Thread project, along with his team, led by lead project chemist Maqsad Suriev. Together, the group has allegedly achieved advancements that can “revolutionize” how textiles are made and used, along with eco-friendly and practical improvements.

“Dr. Hyder Khoja’s role as our senior lead scientist on this project has been indispensable in driving this innovation forward,” Carlson said. “His diverse accomplishments in science and collaborative dedication have combined to pave the way for the mycelium thread’s transformative impact.”

But, in an effort to protect its proprietary technology, the company hasn’t yet disclosed more specific details regarding this process. The “intricate” science behind the mycelium thread will remain under wraps “to protect its intellectual property and maintain a competitive edge,” Mushrooms Inc. said.

“We have brought together many years of innovative research in a short time to bring forth a more groundbreaking textile than Mushrooms Inc. had expected when filing the provisional patent for mycelium thread,” Dr. Khoja said. “We have taken this textile innovation to a new level with microbial detection which we believe, coupled with the natural properties and therapeutic potential of mycelium, will revolutionize the medical sector on a global scale. Being customizable in its attributes allows for endless branches of innovation into vast sectors.”

While the publicly traded company nears the final stages of full patent filing, it’s actively exploring strategic partnerships, investment opportunities and planning for commercialization. Mushrooms Inc. said it’s also exploring licensing opportunities for monetization as well as inviting first-use investors to partake in early-stage funding.

Origin Materials x Terphane

Carbon negative materials company Origin Materials has partnered with specialty PET polyester film producer Terphane to produce sustainable, high-performance biopolymer films.

“We are pleased to partner with Terphane, a trusted global leader in films with expansive customer and partner relationships,” Rich Riley, co-CEO of Origin Materials, said. “We are thrilled to work together to develop advanced, performance-enhanced products that help to enable a net-zero material economy. This partnership represents further progress in Origin’s mission to enable the world’s transition to sustainable materials.”

Per the partnership, Terphane signed a multi-year capacity reservation agreement to buy the bio-polymer polyethylene furanoate (PEF), a 100 percent recyclable, bio-based polymer produced using renewable raw materials, for use in film applications, including food and beverage packaging and industrial applications. BOPEF is biaxially oriented PEF, while BOPET is biaxially oriented PET. Biaxial orientation refers to a process whereby a plastic sheet or film is stretched so that the polymeric chains are oriented parallel to the film’s plan. And these stretched polymer films are valuable, the company said, for their electrical insulation, barrier properties, strength and transparency. Initial tests in the United States have shown that the material works “perfectly” in extrusion lines.

“The development of this film will be critical to our efforts to meet this new global demand for sustainable flexible packaging solutions,” Marcos Vieira, global director of R&D for Terphane, said. “The film is partially made from PEF and has all the traditional properties of a regular PET film, including post-consumption recycling. In addition, PEF provides an excellent thermal resistance and superior barrier performance, extending the shelf life of the packaged products.”

Origin Materials’ patented technology platform represents a “potential breakthrough,” the California company said, in the commercialization of cost-competitive and low-carbon PEF. Made from furandicarboxylic acid (FDCA)—a predecessor of PEF—Origin PEF will be a 100 percent plant-based polymer fully recyclable and expected to offer a significantly reduced carbon footprint. Compared to petroleum-based materials, Origin PEF has superior strength and thermal and barrier properties to widely used packaging materials.

Solve the daily Crossword