Why Nike Forward Is the Brand’s Most Advanced Innovation in Apparel Since Dri-Fit

Throughout its 50 years, Nike has pushed the envelope when it comes to sustainability, delivering game-changing materials and collections such as Flyleather and “Space Hippie” footwear. The sportswear giant’s latest eco-friendly effort is in the apparel space: Nike Forward.

Nike Forward — which the brand described as a platform, not a product — is a dramatic shift away from traditional knit and woven processes, and has been in research and development for more than five years.

More from Footwear News

“One of the biggest ahas for me was close to five years ago when we showed our early ideation with one of our trusted Nike editor executives. They gave us the advice to not try to make this like a knit or a woven, and to embrace everything that was unique about it. That was a big pivot point for us,” Nike Inc. VP of innovation apparel design Carmen Zolman told FN. “We embraced that it’s a completely new class of thing, embraced that it’s sustainable from the ground up and embraced that it’s going to provide performance for the athlete in a completely new way.”

Nike Forward has been labeled by the company as its most significant apparel innovation since Dri-Fit.

“It feels weighty and exciting. We’ve literally spent over five years innovating from the ground up. The past 50 years, Nike would have been all about the performance. Now we’re about the performance and sustainability side by side. That is revolutionary and it will change everything we do in apparel — and potentially even footwear,” Zolman said.

Courtesy of Nike

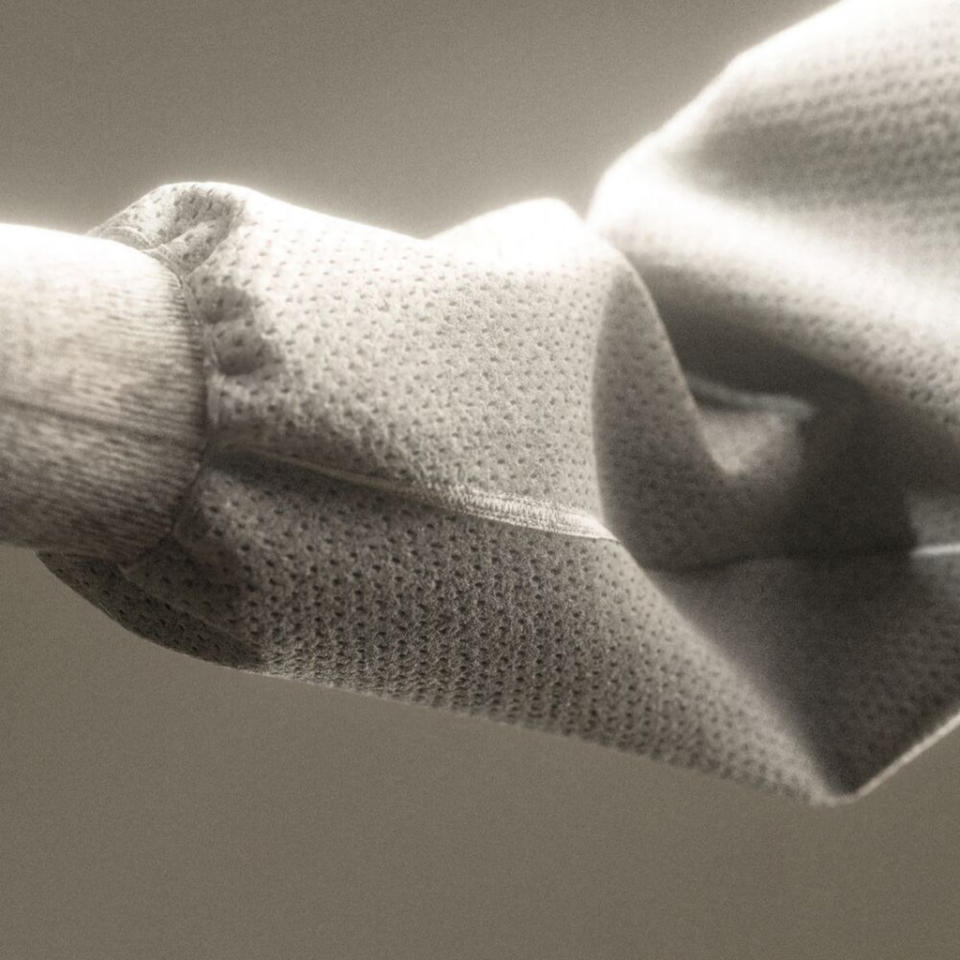

To create the Nike Forward process, the brand discovered a new way to use existing needle-punch machinery in a way that could reinvent how premium, sustainability-focused apparel is made.

“This needle punch technology we found in the medical and automotive worlds. In the medical world, they typically don’t care about durability. We needed to solve for that. We spent a good portion of our last five years solving for a consumer to buy this, own it, wear it, wash it time and time again and last as long as it can,” Zolman explained. “The automotive industry, they don’t care about the hand feel and the softness. We’ve spent a large part of the last five years with our creatives, our scientists with a little bit of that Nike magic to figure about how we can get the hand feel to be really soft.”

Breaking down the process, Nike said the material fabrication is simplified by reducing the number of steps, deviating from the multistage creation cycle that includes spin yarn, knit, cut, sew and more. Multiple thin layers are connected, according to Nike, using a needle punching process that entangles them together to create an end textile. Nike stated it started with a composite of five thin layers, but said there is limitless potential to change the makeup.

With the reduction of steps comes a better impact on the environment. For starters, Nike stated less energy is consumed, which leads to a carbon emissions reduction by an average of 75% compared to its traditional knit fleece. Also, the brand said the material has a lighter density than traditional knit fleece, which was important to achieving the 75% carbon reduction, and Nike Forward is made with at least 70% recycled content by weight.

“We start everything digitally on avatars. Every season we convert more and more to being fully digital so that by the time we get to an actual make stage, our accuracy and our fidelity is that much closer to perfection and we don’t need to do the multiple sample rounds or with any downstream partners,” Zolman said.

Courtesy of Nike

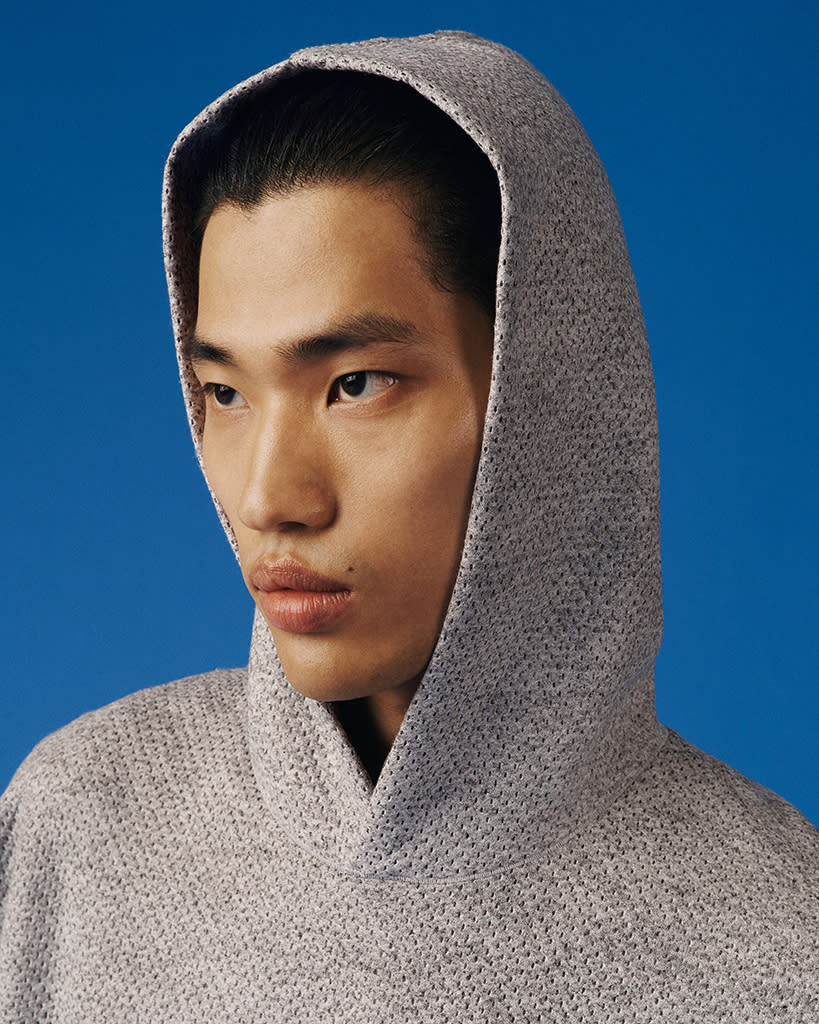

The Swoosh will debut the innovation on a fall staple: a gray hoodie. This hoodie, however, is executed with an atypical look, featuring minimal seams, raw cut pockets and what Nike described as a sculptural fit. The innovation, according to Nike, breaks in over time like jeans or a heavy-weight sweatshirt.

The Nike Forward hoodie, as well as a crew, will launch for men and women on Sept. 8. The first hoodie made with Nike Forward, the brand said, uses zero water in dyeing and finishing. Also, the company stated the first iteration of Nike Forward products are made without zippers, aglets or extra trims, which will make it easier for the garments to be recycled.

Courtesy of Nike

Courtesy of Nike

Courtesy of Nike

Courtesy of Nike

Courtesy of Nike

Courtesy of Nike

Courtesy of Nike

Courtesy of Nike

Best of Footwear News

Sign up for FN's Newsletter. For the latest news, follow us on Facebook, Twitter, and Instagram.