Material World: Starboard Vest Sets Sail with Kelsun Fiber Blend

Material World is a weekly roundup of innovations and ideas within the materials sector, covering news from emerging biomaterials and alternative leathers to sustainable substitutes and future-proof fibers.

Keel Labs

Keel Labs and product designer Mr. Bailey partnered to create the Starboard Vest, a one-of-a-kind piece made with the North Carolina-based startup’s flagship product, the seaweed-based Kelsun fiber.

More from Sourcing Journal

Kelsun’s “oceanic origins” and Keel Labs’ desire to offer designers a more sustainable alternative to conventional materials made the partnership a natural fit, the duo said, expanding Mr. Bailey’s design work at the intersection of nature and technology.

“I genuinely believe that impactful design starts at the material level. Collaborating with the team at Keel Labs has been enlightening—they’re not only harnessing seaweed to create fibers but are also intelligently integrating these innovations into current textile production processes,” Mr. Bailey said. “It’s this mix of idealism and pragmatism that resonates with me. I’m thankful to Keel Labs for allowing my team and I the liberty to explore the potential of Kelsun fiber and demonstrate just a glimpse of what their material can achieve.”

The vest was constructed with a 50/50 split of Kelsun fiber and a cotton blend. It features three successive layers of different knit constructions, utilizing a trapunto technique to connect the exterior shell and contrasting ribs. Mr. Bailey filled the vest with 100 percent Kelsun fiber to “inflate” the garment’s shape and structure as well as pay homage to life vests onboard marine vessels.

“It was a privilege to work with Mr. Bailey to bring his vision of Kelsun to life in the thoughtful and detailed execution of the Starboard Vest,” said Tessa Callaghan, Keel Labs’ co-founder and CEO. “Through Mr. Bailey’s vision, we were able to push Kelsun beyond its creative limits—creating a truly unique design that unites next-gen materials, biomimicry, and the art of garment construction.”

Gen Phoenix

In line with the 2024 Met Gala, themed “Sleeping Beauties: Reawakening Fashion,” London-based Gen Phoenix has coined the word “luxcycling.” The portmanteau of luxury and recycling translated to “the action of creating luxury products from recycled materials, bringing new life to garments that would otherwise be wasted.”

“’Luxcycling’ describes a significant macro trend we’re currently witnessing across the fashion industry. Increasingly, brands are under pressure to embrace sustainability while also meeting consumer demands to maintain the same high-quality and luxury associated with their core products,” Gen Phoenix CEO John Kennedy said. “This is particularly true of luxury and heritage leather brands, and luxcycling gives vocabulary to the ways brands are using innovative materials and proprietary manufacturing processes to extend the lifespan of pieces.”

The firm, which reengineers leather production scraps into new materials, also announced the newly minted name for its luxury material: Aurora.

Crafted from reclaimed leather waste using Gen Phoenix’s patented technology, Aurora translates waste leather into fibers—“entangling” them around a high-performance core using recycled high-pressure water. Depending on brand partner specifications, Aurora includes up to 77 percent recycled content.

“This material innovation epitomizes luxury while upholding our dedication to sustainability, resulting in a sustainable material that is both soft to the touch and exceptionally durable,” Kennedy said. “Through meticulous attention to detail and innovative sustainable practices integrated into every step of its production, Aurora embodies our core values, ensuring that each product upholds the highest standards of quality and environmental responsibility.”

Aurora is intended for the luxury market, including leather goods, footwear and accessories. Through the Coach collaborator’s patented technology, the firm can customize the product’s finish and grain based on its brand partners’ preferences.

“At Gen Phoenix, we believe sustainability only truly matters if it can be achieved at scale, and Aurora unlocks the ability to demonstrate how this is possible,” Kennedy said. “We recognize that true impact hinges on developing a material that aligns with the performance, planet, and price requirements set by heritage leather brands, and we’re proud to deliver that through this material innovation.”

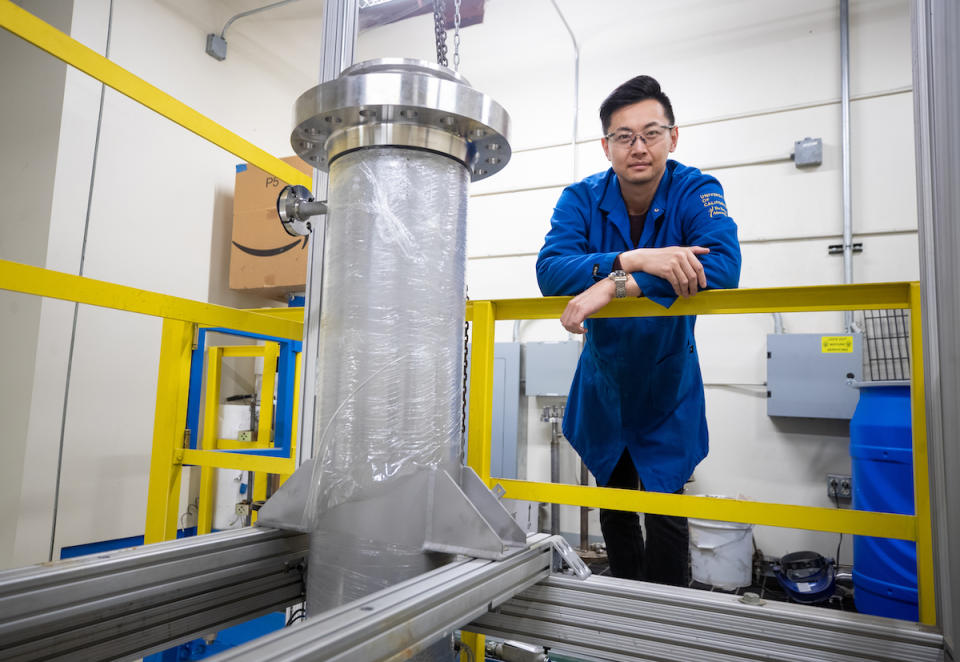

University of California

A professor at the University of California Riverside (UCR) received a $1.45 million federal grant to scale up sustainable biomass-to-fabric innovation.

The Department of Energy (DOE) grant will fund further development of a process invented by UCR associate research professor Charles Cai that turns biomass into a viscous dissolving pulp that can be made into lyocell.

Cai’s process, called CELF (co-solvent enhanced lignocellulosic fractionation), reduces carbon emissions and air pollution as it doesn’t involve burning and uses 50 percent less energy to produce the same grade of dissolving pulp from plant waste. The biomass pretreatment technology extracts lignin—a natural phenolic polymer and the second most abundant polymer on Earth, following cellulose—from wood chips and other plant-based biomass.

The process can also be “intensified” to make biofuels, including jet aircraft fuel. Last year, Cai received a $2 million grant from the DOE to advance CELF for making this jet fuel.

“By using CELF, we can completely eliminate the production of black liquor, not only making the emissions of the entire operation cleaner but also substantially reducing the amount of energy and the operating cost,” Cai said to UCR News. “We can also use a variety of different feedstocks. We’re not limited to just using trees or tree waste, but we can also use agricultural wastes like sugar cane, corn stover, and even industrial hemp.”

The grant will allow Cai to scale up the process to produce 100 times more pulp than his previous laboratory-scale reactor. At UCR’s College of Engineering Center for Environmental Research and Technology (CE-CERT), Cai is assembling equipment to demonstrate this pilot plant. The pulp made at CE-CERT will be sent to the University of Knoxville to be bleached using a cleaner elemental chlorine-free method to produce dissolving-grade pulp. That bleached dissolving pulp will then be forwarded to UCR’s commercial cost-share partners, MG Fuels and The Hurd Co., where it will be extruded and spun into lyocell.

Solve the daily Crossword